Hanging Gate Stopper: Selection and Installation

A hanging gate track stopper is a critical safety component. This hardware part serves as a limit stop for roller carriages, preventing them from sliding out of the track and ensuring a smooth stop of the gate leaf at designated points.

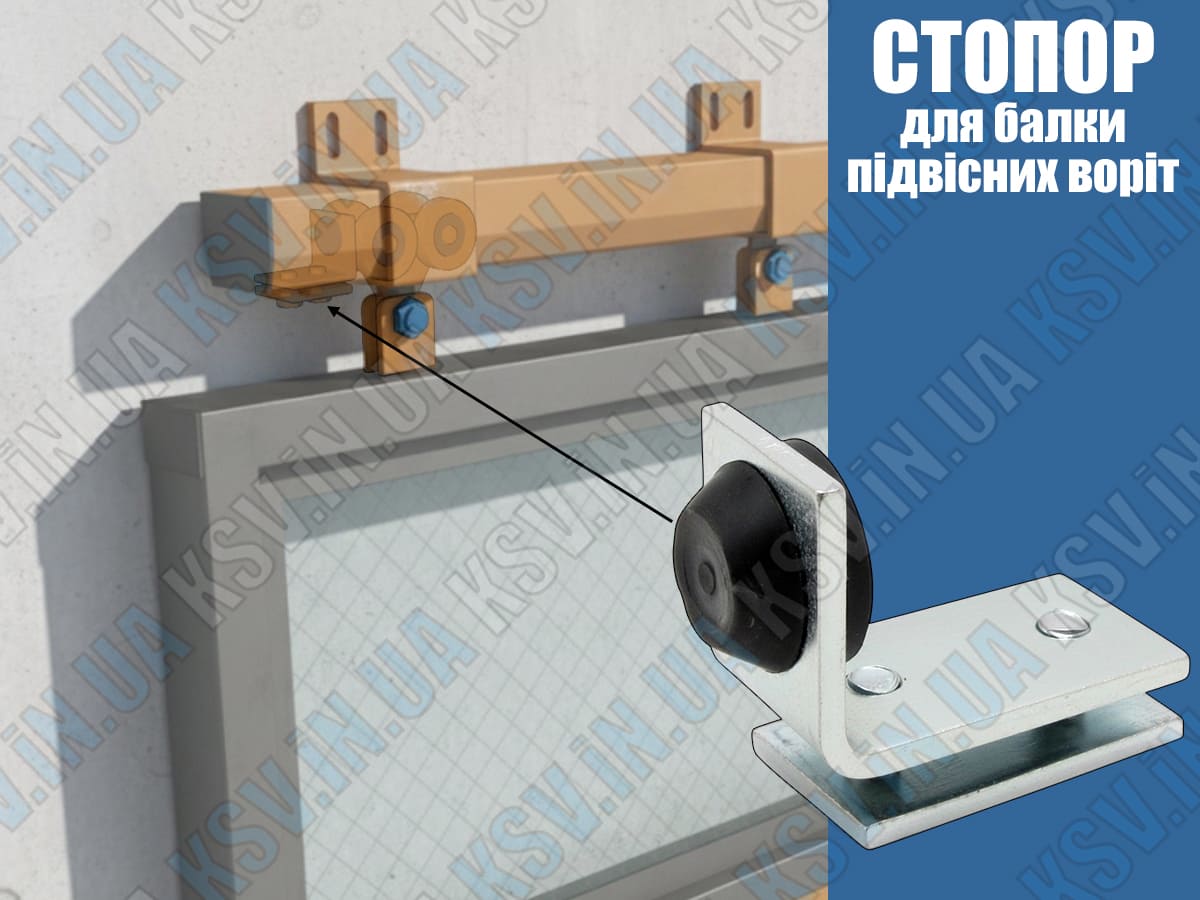

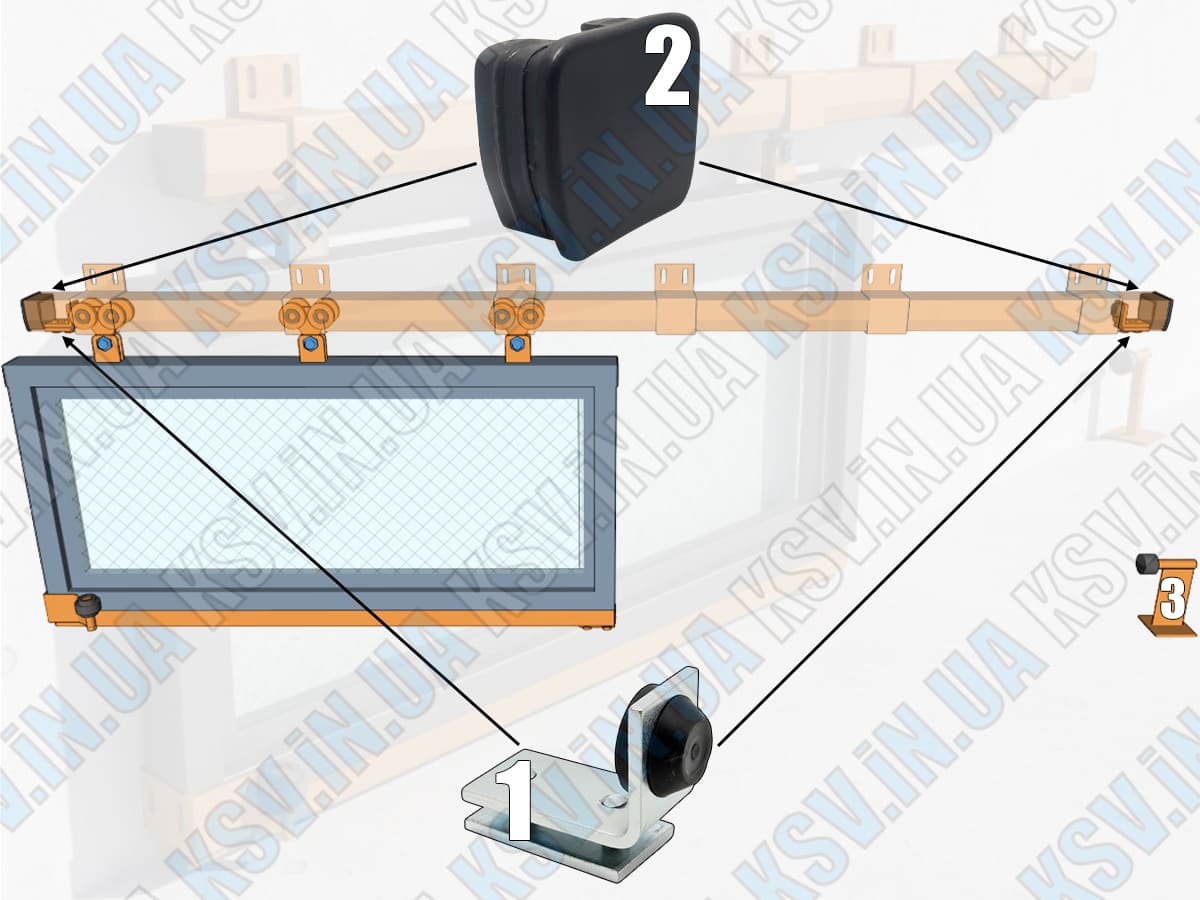

Fig. 1 — Element layout: 1. Internal stopper; 2. Track end cap; 3. Bottom limiter.

Why Do Hanging Systems Need a Stopper?

In hanging gate systems, the main dynamic load falls on the upper track. The absence of a high-quality limiter carries serious risks:

- Carriage Derailment: Gate inertia can cause the rollers to fly out of the profile.

- Premature Wear: Harsh "metal-on-metal" impact damages the roller carriage bearings.

- Automation Error: The stopper provides a stable end point required for the correct operation of the electric drive.

Types of Limiters and Their Functions

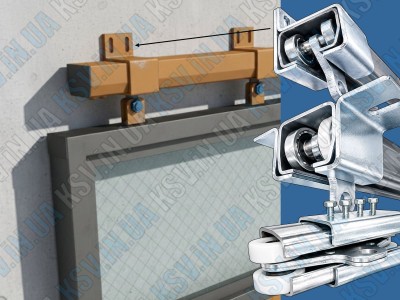

№1: Internal Stopper Mounted directly inside the track profile. Equipped with a rubber damper that effectively absorbs the carriage's impact energy. Hidden mounting protects the part from corrosion.

№3: Bottom Stop Installed externally at the lowest stop points of the gate frame. Equipped with a damper that cushions the impact of the entire hanging structure, preventing swaying.

Technical Selection Criteria

| Specification | KSV Systems Requirement |

|---|---|

| Profile Size | Exact match to the internal track section (mm) for a tight fit. |

| Damper Material | Frost-resistant rubber (maintains elasticity down to -30°C). |

| Coating | Galvanic zinc plating (at least 8 µm layer) for rust protection. |

Step-by-Step Installation Guide

- Marking: Move the gate to the extreme position (open/closed) and mark the carriage fixation point.

- Installation: Insert the stopper (№1) into the track with the damper facing the rollers.

- Fixation: Tighten the locking bolts on the stopper body as firmly as possible.

- End Caps: Install rubber end caps (№2) at the ends of the upper track to protect against debris and precipitation.

Engineer's Tip: For stable operation, we recommend leaving a technical offset — 25 cm from the track edge to the center of the roller carriage (in both "open" and "closed" positions). This space is necessary for proper stopper and end cap placement.

Looking for professional hanging system hardware?

Choose components at KSV Systems store