Roller Carriage for Overhead Sliding Gates: Selection and Installation

Overhead sliding systems are the gold standard for reliability and maintainability. Unlike cantilever systems, there is no load on the foundation, and the drive mechanisms are fully protected from harsh environmental conditions. In this guide, we will look at how to choose the right components and build "everlasting" gates yourself.

Article Contents:

The Secret to "Indestructible" Overhead Structures

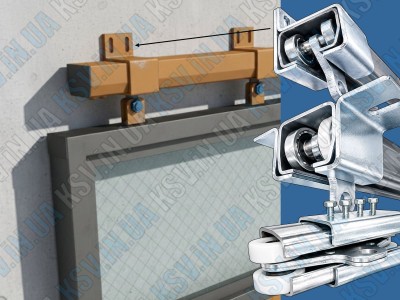

The gate frame moves along the upper guide rail (track) via roller carriages. A common myth among beginners: "The track might bend under the weight of the gate leaf."

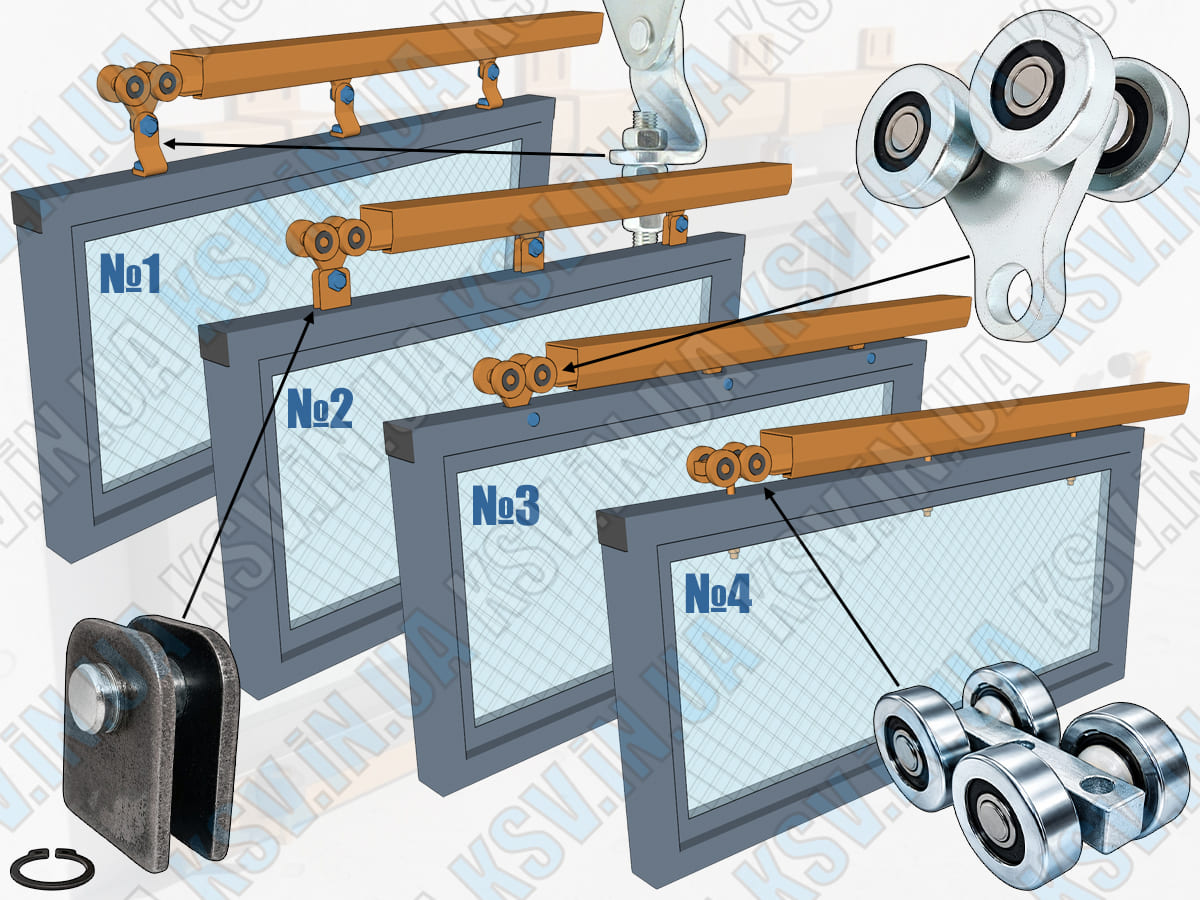

The Golden Rule of Durability: the more carriages used, the longer the supporting bearings last. For a 4-meter opening, 2 carriages are sufficient, but installing 4 or 6 units distributes weight so effectively that the system's service life increases several times over.

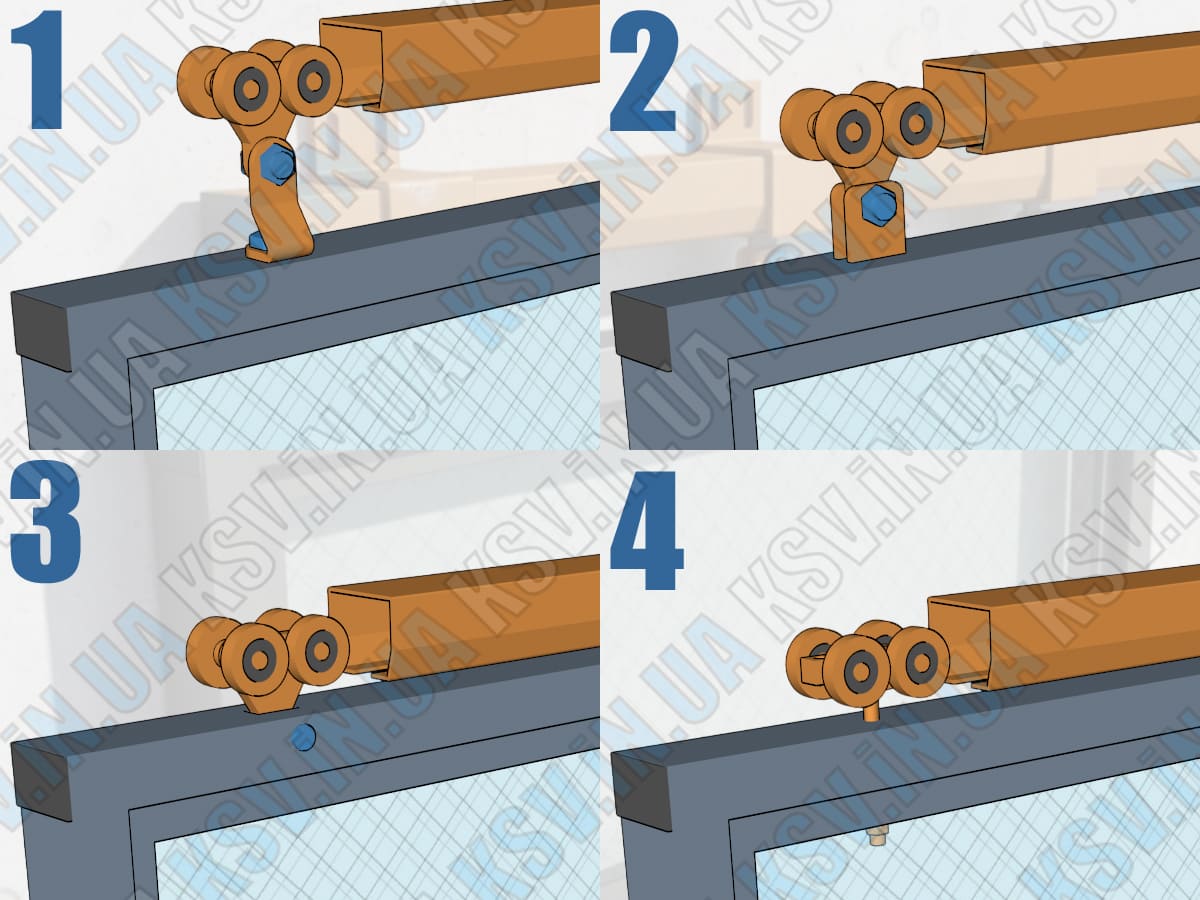

4 Proven Methods of Carriage Mounting

How to Properly Choose a Roller Carriage?

When purchasing hardware, refer to the technical parameters in the table below:

| Parameter | What it Affects |

|---|---|

| Frame Weight | Determines the required size and thickness of the guide track. |

| Roller Material | Steel rollers for heavy gates; polymer rollers for silent operation. |

Online Calculator

Calculate the required number of rollers based on your gate weight:

Go to Calculator →Summary

When choosing a roller carriage, remember: a safety margin is never redundant. Properly selected hardware and a reinforced guide track guarantee system operation for decades.

Material prepared by KSV Systems specialists.